No 32, 4th main, Kalyan Nagar, Nagarbhavi Main Road, Bengaluru

meeting all your AUTOMATION needs

Cutting Edge Automation Technology

Aptitude Solutions is specialized in providing Industrial Automation

Solution to various industry verticals.

Get Automation consultation for

your Business.

Call Us

9483605603

WHO WE ARE?

By combining the real and the digital worlds Using industrial Automation, We empower our clients to transform their industries to be productive, effective, smart industries

Commitment

Our commitment to innovation shows through a continuous, market-driven evolution of products and technology. We believe that if our product meets our expectations, it will exceed yours. And we back these products with a global quality work and dedicated field representatives who stand ready to support our customers, wherever they are.

Quality

Preventing mistakes at the source can significantly improve productivity by keeping mistakes from becoming bigger problems downstream. Banner’s expertise allows us to offer optimal solutions to detect defects, measure components, monitor tolerances, verify product attributes, and reduce the possibility of mistakes or errors–all while increasing quality to a very high standards.

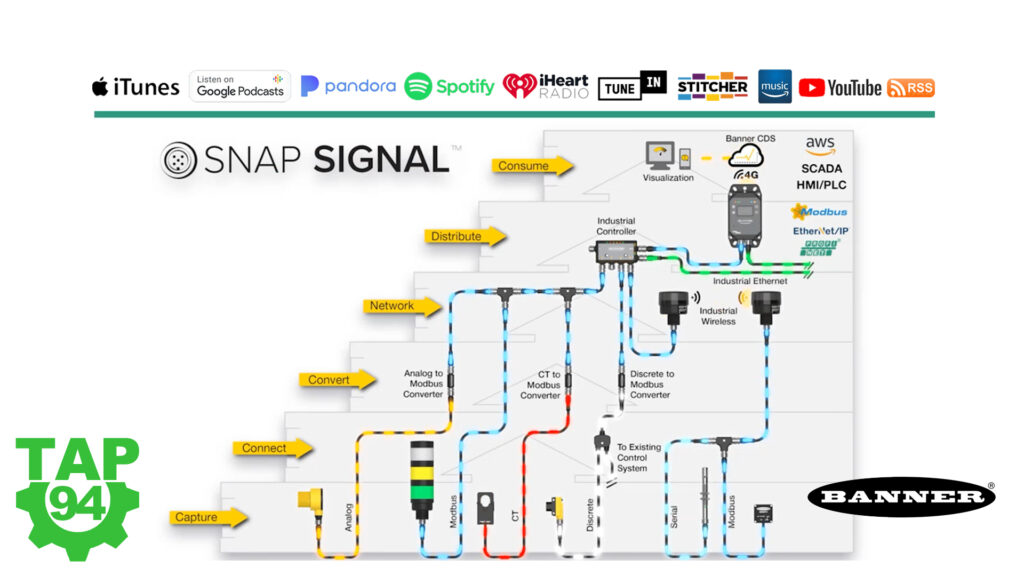

Expertise in IIOT Automation

We are experts in automation processes and technology. Our team of application engineers, industry specialists, and sales representatives have the training and expertise to understand your business, offer leading solutions, and support your operation. We provide continuous education on the latest technologies and industry trends to ensure that our staff and channel partners are thoroughly prepared to solve the most challenging applications..

On We are always focused on

Success defined in a dedication integrity Innovation and Quality work

Banner’s sensors, measurement solutions, LED lights and indicators, machine safety, and industrial wireless tools are at the heart of automation. From Fortune 500 leaders to innovative startups, Banner’s award-winning products and solutions are helping companies around the world increase efficiency, reduce costs, safeguard equipment, and protect personnel. Across industries, we are the trusted partner for solving your application needs, furthering your pursuit of smart automation.

- Material Handling & Logistics

- Automotive

- Packaging

- Electronics

- Agriculture

- Traffic and Parking

- Mobile & Port Equipment

- Food Manufacturing

- Beverage Manufacturing

- Assembly and Robotics

- Semiconductor

- Pharmaceutical and Medical

Automation Products

Innovative Products and Technologies

New Products

S4B HEAVY-DUTY TYPE 4 SAFETY LIGHT CURTAIN R90C SERIAL ANALOG OUTPUT HUB S15S NON-CONTACT INFRARED TEMPERATURE SENSOR

New Applications

Predictive Maintenance Made Easy with Banner’s Wireless Vibration Solution

Remote Monitoring to Optimize Overall Equipment Effectiveness

Featured Products

S4B Heavy-Duty Type 4 Safety Curtains

DXMR90 Series

Multi-Purpose Photoelectric Sensor

Programmable Multicolor Pick-to-Light Touch Button

SUCCESS STORIES

Wireless Vibration Monitoring

To solve the company’s need for predictive maintenance, they turned to Banner’s wireless vibration monitoring solution.

Banner’s vibration machine learning algorithm was used on the DXM wireless gateway to baseline and automatically set alert thresholds for each of the three sensors.

After three months of consistent vibration levels, workers observed a clear rise in vibration levels on one of the pillow block bearings that was being monitored. Upon replacement and inspection of the disassembled bearing, the technician saw spalling on the inner race of the bearing.

After the new bearing was installed, a new vibration baseline and alerts were generated by the machine learning algorithm for ongoing monitoring of the air handling system shown below.

By identifying the mechanical failure early, the scheduled replacement prevented an emergency visit that would have cost two to three times the normal price of maintenance. Without it, there may have been additional damage to the air handling system, causing required workers to stay out of the office until a solution was found, and resulting in added costs and reduced worker production.